Technology Automotive – Variable Valve System Intelegent Timing Owned by Toyota Car – Toyota has a VVT-i (Variable Valve Timing with intelligence) VVT-i engine is actually developed by Toyota. VVT-i is a replacement or upgrading of previous technologies that VVT owned by Toyota company has long been applied and used in early 1991. Toyota’s VVT-i engine has its own advantages so that new technology engine is more efficient and powerful than that he is also friendly environment and fuel efficiency. In driving a VVT-i engine we have to learn and know about the foundation of the creation of VVT-i technology because it wants to optimize the engine torque either in terms of speed atapun in driving conditions can be comfortable in every field of travel and not wasteful when the car is fuel consumption therefore it will be more efficient and environmentally friendly because VVT-i has lower air pollution levels such as fuel emissions can have the lowest level possible.

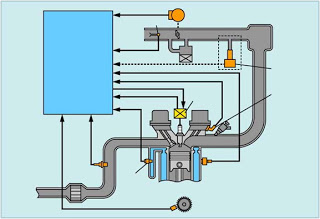

How does it work? The way it works is quite simple. To calculate the optimal valve timing opening time, the ECU (Electronic Control Unit) adjusts to engine speed, incoming air volume, throttle position (accelerator) and water temperature. In order for the target valve timing always to be achieved, the chamshaft or crankshaft position sensor provides the signal as a correction response. The simplest language of the VVT-i system will continue to correct the valve timing or fuel and air inlet. Adjusted with a gas pedal footing and load borne for optimum torque in each round and engine load.

Adoption of VVT-i technology to the car engine also gives the excess lack of maintenance costs to be borne. Because tune-ups like valve set and so on are not needed anymore. However, you should still do regular service, avoid careless workshop, and use engine oil with the required grade in accordance with the manual issued by the car manufacturer. Choosing any workshop for this car to be abstinence, the article of this machine requires a special diagnostic computer that is only available dibengkel official.

Cars Basic Techniques Driving with automotive VVT-i technology

Driving a VVT-i engine properly can save fuel usage by up to 30% compared to conventional engines. However, riding origin generates waste of up to 20% compared to conventional machines. Compared to conventional engines, the VVT-i engine produces great torque at low engine speed and horsepower (abundant) in high engine rotation. Well here are tips on driving a car that uses VVT-i engine

First, study the characteristics of the VVT-i engine. Usually the timings will change between low speed and fast rotation at 3000 rpm. This can be felt usually faster acceleration after passing the rpm.

Second, then check on the engine rotation how many vehicles can move (flat and flat road). This is the lowest rpm where VVT-i produces 90% of torque, usually 2000 rpm.

Third, then you need to change your driving habits. Move teeth just before the timing change occurs, eg at 3000 rpm there is a change in timing then, move teeth at 2950 rpm.

Variable Valve System Intelegent Timing

It seems like you’re asking about a Variable Valve Timing (VVT) system, specifically one that is “intelligent” or more advanced. In automotive engineering, Variable Valve Timing refers to a technology used to optimize the timing of a vehicle’s engine valves in order to improve performance, efficiency, and emissions.

Intelligent Variable Valve Timing (i-VVT)

In the context of “intelligent” VVT, manufacturers often use electronic control systems to fine-tune the timing of the intake and exhaust valves based on various factors such as engine speed, load, and temperature. This allows the engine to adapt to different driving conditions, improving both power output and fuel efficiency. The “intelligent” aspect usually refers to systems that use sophisticated algorithms and sensors to make real-time adjustments to the valve timing.

How It Works

- Valves and Timing: In a typical internal combustion engine, the intake and exhaust valves are controlled by a camshaft. The camshaft’s position determines when the valves open and close. Normally, this timing is fixed, but with VVT, the position of the camshaft can be adjusted to change the valve timing.

- Sensors and Actuators: In an intelligent VVT system, sensors measure various parameters (e.g., engine speed, load, and temperature), and an actuator adjusts the camshaft position to optimize performance.

- Advantages:

- Improved Fuel Efficiency: The system can adjust the valve timing for lower emissions and better fuel economy at lower speeds.

- Increased Power: At higher engine speeds, the system can adjust to allow more air and fuel into the cylinders for better power output.

- Reduced Emissions: Optimizing the combustion process leads to more complete fuel burning, reducing harmful emissions.

Examples of Intelligent VVT Systems:

- VVT-i (Variable Valve Timing with intelligence) by Toyota

- VTEC (Variable Valve Timing and Lift Electronic Control) by Honda

- VANOS (Variable Nockenwellen Steuerung) by BMW

- MIVEC (Mitsubishi Innovative Valve timing Electronic Control) by Mitsubishi

Each manufacturer uses its own specific implementation of VVT, but the general concept remains the same: variable timing to optimize engine performance.

Would you like more detailed information about a specific VVT system or how it works in a certain vehicle model?

VVT-i (Variable Valve Timing with intelligence)

VVT-i (Variable Valve Timing with intelligence) is a variable valve timing technology developed by Toyota to optimize engine performance and fuel efficiency. VVT-i adjusts the timing of the engine’s intake valves based on engine speed and load, allowing for better fuel efficiency at lower speeds and more power at higher speeds. The “intelligence” in VVT-i refers to its ability to make real-time adjustments to the valve timing using an electronic control system, maximizing engine performance under various driving conditions.

Key Features of VVT-i

- Dynamic Valve Timing:

- VVT-i continuously varies the timing of the intake valves. By adjusting when the valves open and close, it improves the engine’s ability to breathe, allowing more air (and therefore fuel) to enter the combustion chamber.

- The timing is altered based on factors like engine RPM, throttle position, and load.

- Improved Fuel Efficiency:

- At low speeds or light loads, the system advances the valve timing to improve fuel efficiency. The engine runs more efficiently because the intake valves close earlier, reducing pumping losses and improving combustion efficiency.

- At high speeds or heavy loads, the system retards the timing to allow for more air-fuel mixture to enter the engine, increasing power output.

- Better Performance and Power:

- At higher RPMs, VVT-i allows the intake valves to open later, giving the engine more time to intake air and fuel. This increases the volume of air-fuel mixture entering the cylinders, which boosts power.

- Emissions Reduction:

- By optimizing the air-fuel mixture and improving combustion efficiency, VVT-i helps reduce the emission of pollutants, contributing to cleaner exhaust gases.

- Electronic Control:

- Unlike older, purely mechanical VVT systems, VVT-i uses an electronic control unit (ECU) to control an oil-pressure-driven actuator that adjusts the camshaft timing. This provides greater precision and the ability to adapt to changing driving conditions.

- Continuous Adjustments:

- VVT-i makes these adjustments continuously and seamlessly while the engine is running. The system is designed to be fast and responsive to changes in driving conditions, ensuring that the engine is always operating in an optimal state.

Components of VVT-i:

- Camshaft Gear: The camshaft gear is connected to an actuator that adjusts the camshaft’s position.

- Actuator: This is driven by engine oil pressure and is controlled electronically by the engine’s ECU.

- Timing Adjuster: The adjuster moves the camshaft to advance or retard the timing of the intake valves.

- Sensors: Sensors monitor variables like engine speed, throttle position, and load, providing real-time data to the ECU.

VVT-i vs. VVT-iE

Later generations of the VVT-i system, such as VVT-iE (Variable Valve Timing with intelligent Electric motor), introduced an electric motor for even finer control of the camshaft. This allows for more precise adjustments, further improving fuel efficiency, performance, and emissions.

Benefits of VVT-i:

- Improved Fuel Economy: The system allows the engine to adjust to different driving conditions, making it more fuel-efficient in a wide range of situations.

- Enhanced Power: By optimizing the valve timing, VVT-i allows for more air-fuel mixture to enter the engine, improving performance, especially at higher RPMs.

- Reduced Emissions: By ensuring that the engine runs as efficiently as possible, VVT-i helps minimize the output of harmful emissions.

- Smooth Driving Experience: VVT-i ensures the engine is always operating in the best possible state, leading to smoother acceleration, quieter operation, and better overall driving dynamics.

VVT-i in Practice:

VVT-i has been used in a wide range of Toyota’s vehicles, from compact cars like the Toyota Corolla to larger sedans, SUVs, and even trucks like the Toyota Tacoma. It has also been implemented in various engine configurations, including inline-4, V6, and hybrid engines.

- Toyota Corolla (1.8L engines): Early adoption of VVT-i helped improve both fuel efficiency and power output, making the Corolla one of the most fuel-efficient cars in its class.

- Toyota Camry (2.5L and 3.5L engines): VVT-i has been used in the Camry’s inline-4 and V6 engines to balance power and fuel economy, making the car both more powerful and more efficient than competitors in its class.

- Toyota Prius (Hybrid models): The Prius uses VVT-i in conjunction with its hybrid system to maximize fuel economy and reduce emissions.

VVT-i Technology Evolution:

- First Generation (VVT-i): Introduced in the late 1990s, it was used primarily to optimize fuel economy and emissions without sacrificing power.

- Second Generation (VVT-iE): This newer version uses an electric motor for even more precise control of the camshaft, further improving efficiency and performance, particularly in hybrid engines.

- VVT-i Dual: A more advanced version of VVT-i that controls both intake and exhaust valve timing. This allows for even better performance, fuel economy, and emissions control.

VVT-i vs. Other Variable Valve Timing Systems:

- Honda’s VTEC (Variable Valve Timing and Lift Electronic Control) offers a similar concept, but it uses a more mechanical system to switch between different camshaft profiles, while Toyota’s VVT-i is continuously variable and uses more sophisticated electronic controls.

- BMW’s VANOS (Variable Nockenwellen Steuerung) is another type of variable valve timing, but it focuses on changing the timing of both intake and exhaust valves, which allows for a broader performance spectrum.

In summary, Toyota’s VVT-i system is a critical component in making their engines more fuel-efficient, cleaner, and more powerful. It’s one of the key innovations that has helped Toyota stay at the forefront of automotive technology, particularly in terms of balancing performance with environmental concerns.

VTEC (Variable Valve Timing and Lift Electronic Control) by Honda

VTEC (Variable Valve Timing and Lift Electronic Control) is a variable valve timing technology developed by Honda that improves engine performance by allowing the engine to use multiple camshaft profiles depending on driving conditions. It optimizes the engine’s valve timing and lift characteristics to enhance power output at high RPMs while maintaining fuel efficiency and smooth operation at lower RPMs.

Key Features of VTEC:

- Multiple Camshaft Profiles:

- The most distinctive feature of VTEC is its use of multiple camshaft profiles for different engine speeds. At low RPMs, the engine uses a camshaft profile that maximizes fuel efficiency and smooth operation. At higher RPMs, a different camshaft profile is engaged that allows for more aggressive valve timing and lift, increasing the engine’s performance potential.

- Valve Timing and Lift Control:

- VTEC not only adjusts the timing of the intake and exhaust valves but also changes the valve lift (how far the valve opens). This means the engine can have both optimized fuel efficiency and increased power at higher RPMs, depending on the driving conditions.

- Electronic Control:

- VTEC is electronically controlled through an ECU (Engine Control Unit), which activates and deactivates the system based on the engine’s RPM and load. The system is designed to provide a noticeable boost in performance when the engine reaches higher RPMs, typically around 4,000 to 5,000 RPM, depending on the engine model.

How VTEC Works:

VTEC uses a hydraulic system to engage and disengage different camshaft profiles. The engine has two or three camshaft profiles, each designed for a different performance characteristic. Here’s how the system typically works:

- Low RPM Mode:

- At lower RPMs, the engine uses a camshaft profile that focuses on improving fuel efficiency, smoothness, and low-end torque. In this mode, the valves open and close more gradually, providing a more efficient combustion process at lower engine speeds.

- High RPM Mode:

- When the engine reaches higher RPMs (usually above 4,000 to 5,000 RPM), the ECU activates the VTEC system, which uses a solenoid to direct oil pressure into the VTEC mechanism. This causes a set of rocker arms to “lock” into a more aggressive camshaft profile, which increases the valve lift and alters the valve timing. This allows for greater airflow into the combustion chamber, improving power output.

- Transition:

- The transition from the “low RPM” camshaft profile to the “high RPM” profile is smooth, with little to no hesitation or noticeable “switching” that would be disruptive to the driver. The transition is designed to enhance performance without sacrificing drivability.

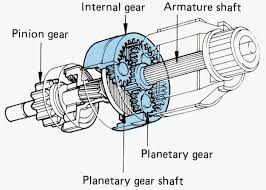

VTEC System Components:

- VTEC Solenoid: A solenoid that controls the flow of oil to the VTEC system. When oil is supplied to the mechanism, it locks the rocker arms to the more aggressive camshaft profile.

- VTEC Rocker Arms: These components allow for multiple cam profiles. The rocker arms can either stay in a “low lift” position or lock into a “high lift” position for better performance.

- Oil Pressure: The system uses engine oil pressure to engage the VTEC mechanism, allowing for quick and reliable switching between cam profiles.

- ECU (Engine Control Unit): The engine control unit monitors engine speed and load and activates the VTEC solenoid at the appropriate RPM threshold.

Types of VTEC Systems:

Honda has developed several variations of VTEC over the years to suit different engine configurations and performance needs:

- Single-Stage VTEC:

- This is the simplest form of VTEC and is used in many of Honda’s earlier engines. It uses two camshaft profiles (one for low RPM and one for high RPM), and the system switches between them when the engine reaches a specific RPM threshold.

- Example: Found in engines like the Honda Civic Si with a 1.6L engine.

- Dual-Stage VTEC (VTEC-E):

- VTEC-E (Economy) is designed to improve fuel efficiency by using an “economy” cam profile for low and medium RPMs, and a more powerful cam profile for high RPMs. It focuses on optimizing fuel economy without sacrificing too much power.

- Example: Found in engines like the Honda Civic VX with a 1.5L engine.

- VTEC with VTC (Variable Timing Control):

- VTC adds another layer of sophistication to the VTEC system by allowing for continuous variable valve timing (similar to Toyota’s VVT-i). VTC adjusts the timing of the intake valves to optimize power delivery and efficiency.

- VTC works in tandem with VTEC to provide even more precise control over valve timing.

- Example: Found in Honda K-series engines, which are used in performance models like the Honda Civic Type R and Honda Accord.

- i-VTEC (Intelligent VTEC):

- i-VTEC is an enhanced version of the original VTEC system that integrates VTEC with additional technologies, like Variable Timing Control (VTC), for even finer control over both valve timing and lift.

- The addition of VTC allows for continuous adjustment of the intake valve timing to improve performance and efficiency at various engine speeds, making it even more “intelligent” than the earlier versions.

- Example: Found in engines like the Honda CR-V and Honda Civic models, as well as Honda Accord and Honda Insight (hybrid).

- VTEC Turbo:

- In some newer turbocharged Honda engines, VTEC is used in combination with turbocharging to enhance both the low-end torque (from the turbo) and high-end power (from VTEC). This hybrid approach takes advantage of both forced induction and variable valve timing.

- Example: Found in Honda Civic Type R and Honda Civic Si with turbocharged engines.

Benefits of VTEC:

- Improved Performance: VTEC allows the engine to provide more power when needed, especially at higher RPMs, without sacrificing efficiency at lower speeds.

- Fuel Efficiency: At low RPMs, the VTEC system optimizes valve timing for better fuel economy, helping to balance power and efficiency.

- Emissions Control: By improving combustion efficiency, VTEC helps to reduce harmful emissions.

- Smoother Driving Experience: The system is designed to engage and disengage smoothly, ensuring that the driver experiences a seamless transition between power modes.

VTEC in Practice:

Honda’s VTEC system has been used in a wide range of vehicles, from fuel-efficient cars to high-performance models. Some of the most famous applications of VTEC include:

- Honda Civic Si (using the 1.6L DOHC VTEC engine)

- Honda Integra Type R (with the high-performance 1.8L DOHC VTEC engine)

- Honda S2000 (with a high-revving 2.0L and 2.2L DOHC VTEC engine)

- Honda Accord (using i-VTEC in both 4-cylinder and V6 engines)

- Honda CR-V (with i-VTEC in 4-cylinder engines for better performance and fuel economy)

VTEC vs. Other Valve Timing Technologies:

- Honda’s VTEC vs Toyota’s VVT-i: Both systems optimize valve timing to improve performance, but VTEC uses multiple camshaft profiles that change at a specific RPM threshold, whereas VVT-i continuously adjusts valve timing for smoother operation and more precise control.

- VTEC vs BMW’s VANOS: BMW’s VANOS (Variable Nockenwellen Steuerung) is a continuously variable system that adjusts the timing of both the intake and exhaust camshafts. While both technologies aim to optimize engine performance, VTEC offers a more distinct “cam profile switch” for a more noticeable power boost at higher RPMs.

In summary, Honda’s VTEC system is a groundbreaking technology that blends fuel efficiency and high-performance driving. It allows for more aggressive valve timing and lift at high RPMs, providing significant power gains without sacrificing fuel efficiency or drivability at lower engine speeds. It has been a key feature in many of Honda’s most popular cars, from everyday sedans and hatchbacks to iconic performance cars.

VANOS (Variable Nockenwellen Steuerung) by BMW

VANOS (Variable Nockenwellen Steuerung) is BMW’s variable valve timing system that adjusts the timing of the intake and exhaust camshafts to optimize engine performance across a wide range of conditions. The word “VANOS” is derived from the German term Variable Nockenwellen Steuerung, which translates to “variable camshaft control.” The system is designed to enhance engine power, fuel efficiency, and reduce emissions by adjusting the camshaft timing depending on engine speed and load.

Key Features of VANOS:

- Variable Camshaft Timing:

- VANOS adjusts the timing of the intake and/or exhaust camshafts. At low RPMs, the camshafts are set for better fuel efficiency and low-end torque. At higher RPMs, the camshaft timing is adjusted to improve airflow and increase power output.

- Hydraulic Actuation:

- The VANOS system is powered by hydraulic pressure, which is controlled by an electronically regulated solenoid. This allows for smooth, precise adjustment of the camshaft positions without mechanical cams or switches.

- Single and Double VANOS:

- Single VANOS: Controls the timing of the intake camshaft only. This was first introduced in the 1990s in BMW’s inline-6 engines.

- Double VANOS: A more advanced version, introduced in the early 2000s, that controls both the intake and exhaust camshafts, offering even greater flexibility and performance optimization.

- Continuous Adjustment:

- Unlike systems like VTEC, which have distinct camshaft profiles for low and high RPMs, VANOS continuously adjusts the camshaft timing within a specified range, ensuring that the engine is always running optimally for the current driving conditions.

How VANOS Works:

VANOS uses hydraulic actuators connected to the camshaft gears, which adjust the position of the camshafts relative to the crankshaft. The system is controlled by the car’s ECU (Engine Control Unit), which determines the optimal camshaft position based on inputs like engine speed (RPM), throttle position, and load.

- At Low RPMs:

- The intake camshaft is adjusted to improve low-end torque and fuel efficiency. The system retards the timing (delays the opening of the intake valves), which helps with smooth idling and better fuel economy.

- At High RPMs:

- The timing is advanced (the intake valves open earlier), allowing for more air and fuel to enter the combustion chamber. This results in more power at higher RPMs, which is crucial for performance driving.

- Continuous Adjustment:

- The hydraulic actuators provide a seamless transition between different camshaft positions, meaning there is no sudden switch or noticeable shift in performance, unlike more traditional systems that may have distinct “switch points.”

Benefits of VANOS:

- Improved Power Delivery:

- By optimizing valve timing for different RPM ranges, VANOS provides more power at high RPMs and better torque at low RPMs. This results in smoother acceleration and more consistent performance.

- Better Fuel Efficiency:

- VANOS improves combustion efficiency, especially at lower speeds, leading to better fuel economy. By adjusting the cam timing based on engine load and speed, the engine can operate more efficiently across a wide range of conditions.

- Reduced Emissions:

- By optimizing valve timing, VANOS helps the engine burn fuel more completely, which reduces the emission of pollutants like unburned hydrocarbons and nitrogen oxides (NOx).

- Smoother Driving Experience:

- VANOS allows for smoother transitions between low and high RPMs without noticeable power gaps or interruptions in acceleration.

Evolution of VANOS:

- Single VANOS: Introduced in the 1990s in BMW’s 6-cylinder engines (like the M50 engine), it only controlled the intake camshaft for improving low-end torque and fuel economy.

- Double VANOS: Later iterations (introduced in the 2000s) controlled both the intake and exhaust camshafts, allowing for even more precise tuning of the engine’s performance at various speeds.

- Valvetronic: A further advancement, Valvetronic is BMW’s system for variable valve lift, which works in tandem with VANOS to control the precise amount of air entering the combustion chamber, offering even greater control over efficiency and power.

VANOS in BMW Vehicles:

BMW has used VANOS technology in a variety of its engines, from naturally aspirated to turbocharged engines, across both standard models and high-performance M cars. Some notable examples include:

- BMW M3 (E46, E90): Equipped with double VANOS in the inline-6 engines, allowing for improved power and torque across the rev range.

- BMW 3 Series (E36, E46): These models featured single VANOS engines in the early years, with the transition to double VANOS in later models.

- BMW 5 Series and 7 Series: Both series incorporated double VANOS technology in their inline-6 and V8 engines for a balance of comfort, efficiency, and performance.

- BMW Z4: The Z4 also used VANOS in its inline-6 engines for enhanced performance and efficiency.

VANOS vs. Other Variable Valve Timing Systems:

- BMW VANOS vs. Honda VTEC: While both VANOS and VTEC optimize engine performance, VANOS adjusts the timing of the camshafts continuously, offering finer control. VTEC, on the other hand, uses multiple cam profiles that switch based on engine RPM, leading to a more distinct shift in engine characteristics.

- BMW VANOS vs. Toyota VVT-i: Like VANOS, Toyota’s VVT-i also adjusts valve timing, but VVT-i is continuously variable and often operates through a single camshaft profile. VANOS, especially in the double version, offers more precise adjustments for both intake and exhaust camshafts.

- BMW VANOS vs. Audi’s VVT: Audi also uses a variable valve timing system, but VANOS tends to offer smoother transitions due to its hydraulic control and the ability to adjust both intake and exhaust valves.

Potential Issues and Maintenance:

- VANOS System Failure: Over time, components like the VANOS solenoids or hydraulic actuators can fail, leading to issues such as rough idling, loss of power, or poor fuel economy. These issues may require repairs or replacement of the faulty components.

- Oil Quality: Since VANOS operates hydraulically, maintaining clean oil and regularly changing it is important to ensure the system functions properly. Dirty or low oil pressure can affect VANOS performance.

- Timing Chain or Gear Issues: In some cases, the timing chain or gears used by VANOS may stretch or wear, affecting the camshaft timing and leading to poor performance or engine misfires.

In conclusion, VANOS is a sophisticated and effective variable valve timing system that helps BMW engines deliver optimal performance, efficiency, and emissions control. By adjusting the camshaft timing based on driving conditions, it ensures that BMWs provide smooth, powerful driving experiences across various models, from everyday sedans to high-performance sports cars.

MIVEC (Mitsubishi Innovative Valve timing Electronic Control) by Mitsubishi

MIVEC (Mitsubishi Innovative Valve timing Electronic Control) is a variable valve timing system developed by Mitsubishi Motors. Like other variable valve timing (VVT) systems, MIVEC adjusts the timing of the engine’s intake and exhaust valves to optimize performance, fuel efficiency, and emissions. However, MIVEC is unique in that it not only adjusts valve timing but also controls valve lift in some applications, which enhances its ability to improve engine performance at both low and high RPMs.

Key Features of MIVEC:

- Variable Valve Timing (VVT):

- MIVEC continuously adjusts the timing of the intake and/or exhaust valves depending on engine speed, load, and other conditions. This allows the engine to optimize combustion efficiency and performance across a wide range of driving conditions.

- Variable Valve Lift:

- In some MIVEC-equipped engines, the system also controls valve lift, or the distance the valve opens. This allows for further optimization of the engine’s breathing capability, improving performance at higher RPMs while maintaining efficiency at lower speeds.

- Electronic Control:

- MIVEC is electronically controlled, allowing for precise and responsive adjustments to valve timing. The system is managed by the engine control unit (ECU), which makes real-time adjustments based on factors such as RPM, throttle position, and engine load.

- Enhanced Efficiency and Performance:

- MIVEC improves fuel efficiency at low RPMs by adjusting the timing to reduce fuel consumption. At high RPMs, the system optimizes valve timing for increased power output, improving engine performance and responsiveness.

How MIVEC Works:

MIVEC operates through a combination of electronic sensors, actuators, and the engine’s ECU. Here’s how the system works in different driving conditions:

- Low RPMs and Light Load:

- At lower engine speeds, MIVEC adjusts the intake valve timing to optimize fuel economy. The system may also reduce the lift of the intake valves for smoother operation and lower fuel consumption, helping to improve low-speed torque.

- High RPMs and Heavy Load:

- As engine speed increases, MIVEC advances the timing of the intake valves (opens them earlier), allowing more air-fuel mixture to enter the combustion chamber. This increases the engine’s power output by optimizing airflow and combustion efficiency. In some applications, the system also increases valve lift, allowing for more air to be drawn into the engine for higher power at high RPMs.

- Smooth Transition:

- MIVEC adjusts the valve timing gradually and seamlessly, so the transition between different valve profiles is smooth and doesn’t disrupt engine performance. The goal is to provide a driving experience that feels natural, with improved fuel economy at low speeds and more power at high speeds.

Components of MIVEC:

- ECU (Engine Control Unit): The ECU manages the system by continuously monitoring parameters such as engine speed, load, and throttle position. It makes adjustments to the valve timing and lift in real-time.

- VVT Actuators: These components adjust the camshaft position to change the valve timing. They are controlled by oil pressure, which is managed by the ECU to adjust timing as needed.

- Valves and Camshafts: The camshafts control when and how the intake and exhaust valves open and close. The camshaft timing and lift can be altered by MIVEC to optimize engine performance at different speeds.

Benefits of MIVEC:

- Improved Performance:

- MIVEC enhances engine performance by allowing the engine to adjust its intake and exhaust valve timing and lift based on operating conditions. This results in more power at high RPMs and improved torque at low RPMs, leading to better acceleration and responsiveness.

- Better Fuel Economy:

- The system helps improve fuel efficiency by adjusting valve timing to reduce fuel consumption during low-speed driving or cruising. The system allows for better combustion efficiency, reducing the amount of fuel needed for the same amount of power.

- Reduced Emissions:

- By optimizing the combustion process, MIVEC helps the engine burn fuel more efficiently, reducing the emission of harmful pollutants like unburned hydrocarbons (HC) and nitrogen oxides (NOx). This contributes to cleaner exhaust emissions and better environmental performance.

- Enhanced Driving Experience:

- MIVEC provides a smooth and responsive driving experience, offering improved low-end torque for city driving and increased power for highway acceleration and high-performance driving.

MIVEC vs. Other Variable Valve Timing Systems:

- MIVEC vs. Honda’s VTEC: Both MIVEC and VTEC adjust the timing of the intake and exhaust valves to optimize performance. However, VTEC relies on a more distinct switch between camshaft profiles (usually one for low RPMs and one for high RPMs), while MIVEC continuously adjusts the camshaft timing and lift to optimize performance across the entire RPM range. MIVEC can also adjust valve lift, which gives it more control over airflow than VTEC.

- MIVEC vs. Toyota’s VVT-i: Both systems adjust valve timing to improve engine performance and fuel economy. However, MIVEC can control both timing and lift (in some engines), whereas VVT-i typically focuses on valve timing alone. MIVEC also allows for continuous changes in both timing and lift, providing more granular control over engine performance.

- MIVEC vs. BMW’s VANOS: BMW’s VANOS adjusts the intake and exhaust camshaft timing to optimize engine performance, whereas MIVEC can adjust both timing and valve lift. VANOS is also more focused on smooth transitions between different engine speeds, while MIVEC offers more flexibility in optimizing both valve timing and lift for different driving conditions.

Types of MIVEC Systems:

- Single-Stage MIVEC:

- The simplest version of MIVEC, which adjusts the intake valve timing to improve fuel efficiency and power at low and high RPMs. This version was initially used in many of Mitsubishi’s smaller engines, like the 1.6L and 1.8L inline-4 engines.

- Dual-Stage MIVEC:

- A more advanced version, which adjusts both the intake and exhaust valve timing. This version is used in larger, more performance-oriented engines, such as those found in the Mitsubishi Lancer Evolution and Mitsubishi Outlander. Dual-Stage MIVEC offers better performance and efficiency across the full range of driving conditions.

- MIVEC with Variable Valve Lift:

- This version of MIVEC controls not only valve timing but also valve lift. This is found in higher-performance engines, such as those used in the Mitsubishi Lancer Evolution X with the 2.0L turbocharged engine. The inclusion of lift control allows for better high-RPM breathing, enhancing power output while maintaining fuel efficiency.

Applications of MIVEC:

MIVEC has been used in a wide range of Mitsubishi vehicles, from small economy cars to high-performance models. Some notable applications include:

- Mitsubishi Lancer Evolution (Evo VIII, IX, X): MIVEC was used in these high-performance turbocharged engines, optimizing power and performance for motorsport and enthusiast applications.

- Mitsubishi Outlander: MIVEC is used in the Outlander’s 2.0L and 2.4L engines to balance performance and fuel efficiency for family and crossover vehicles.

- Mitsubishi Mirage: This small economy car uses MIVEC in its 1.2L engine for improved fuel efficiency and smooth operation.

- Mitsubishi Colt: A subcompact car that also benefited from MIVEC technology to offer better fuel efficiency and low-end power for city driving.

- Mitsubishi Galant: Higher-end models have used MIVEC in their engines to improve both performance and fuel efficiency.

Maintenance and Potential Issues:

- Oil and Filter Maintenance: Like other variable valve timing systems, MIVEC relies on oil pressure to adjust the camshaft timing. It’s essential to maintain clean oil and regularly change the oil filter to ensure that the system operates correctly.

- VVT Actuator Issues: Over time, the actuators or solenoids that control the camshaft timing and lift may wear out or become clogged, leading to a loss of performance or rough idling.

- Timing Belt or Chain Wear: In engines with a timing belt or chain, these components can wear out, leading to poor valve timing and potential engine misfires or power loss. Regular timing component maintenance is crucial.

Conclusion:

MIVEC is a versatile and efficient variable valve timing system that provides significant benefits in terms of both performance and fuel efficiency. Its ability to adjust both valve timing and lift makes it a more sophisticated system than many other VVT technologies, allowing Mitsubishi engines to deliver a more responsive and enjoyable driving experience. Whether in small economy cars or high-performance models like the Lancer Evolution, MIVEC helps Mitsubishi maintain a balance between power, efficiency, and emissions.

That’s a little review about the work system on Toyota cars with technology automotive upgrades from previous technologies that initially the VVT to VVT-i for customer service so comfortable in every condition what may be useful what we write here for you everything. Thanks for visiting (Technology Automotive).